Transforming Product Design by means of Sustainability in Intelligent Manufacturing Facilities

As the a manufacturing landscape keeps to develop, the integration of sustainability into product design has become a critical focus for smart factories. In an era in which environmental concerns are in the forefront of worldwide consciousness, manufacturers face the challenge with not just creating products that satisfy consumer needs and also ensuring that their production processes contribute to the sustainable future. This shift requires a rethinking of how products should be designed, manufactured, and ultimately consumed.

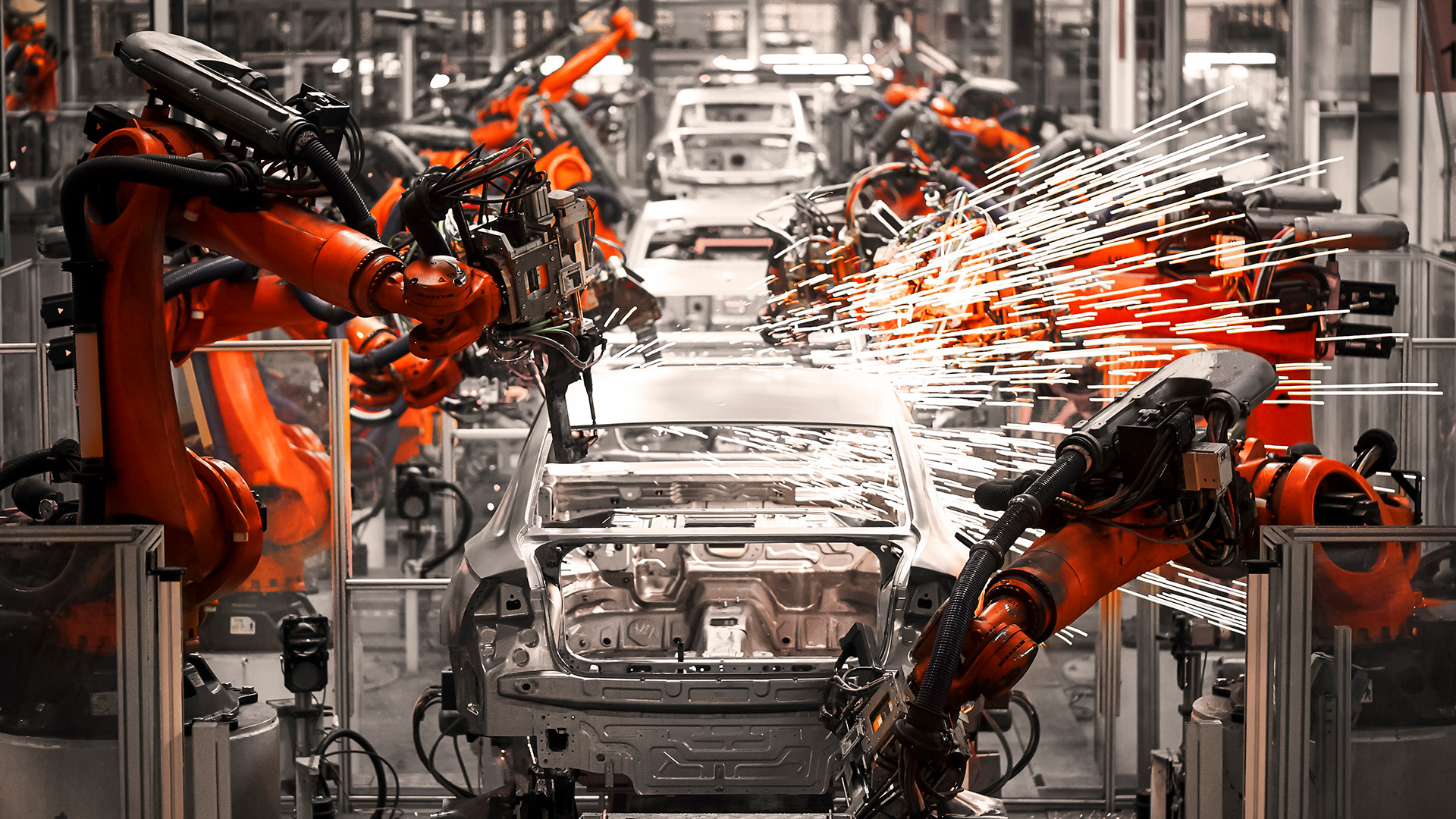

Smart factories represent in the heart of this transformation, leveraging advanced technologies such as artificial intelligence, the Internet of Things, and automation to streamline operations and enhance efficiency. Through the incorporation of sustainable practices into all phases of product design, these facilities can significantly reduce waste, lower carbon footprints, and promote using eco-friendly materials. This paradigm shift not only supports environmental goals and it resonates with a growing base of consumers who prioritize sustainability in their purchasing decisions.

The Value of Sustainability in Product Design

Sustainability in product design is no longer a option; it has turned into a core essential in the modern production landscape. As consumers increasingly favor eco-friendly products, companies must adjust to fulfill this need. Embracing sustainable practices deals with not only environmental concerns and improves a business's brand reputation, ultimately influencing consumer choices. By developing products that reduce waste and leverage renewable resources, manufacturers can create a competitive edge while contributing positively to the planet’s health.

Additionally, sustainable product design encourages innovation and efficiency within the production process. By concentrating on life cycle assessments and sustainable materials, companies can uncover opportunities to minimize energy consumption and lower production costs. This transition not only maximizes resource utilization and nurtures a culture of continuous improvement, where organizations seek to innovate solutions that are cost-effective and environmentally responsible. Such progress can lead to the creation of advanced factories that focus on sustainability and productivity.

Finally, integrating sustainability into product development promotes cooperation across various stakeholders, including suppliers, manufacturers, and consumers. This collective approach encourages the sharing of effective methods and resources, creating a broader impact on the industry as a whole. When companies focus on sustainable design, they are not just improving their own operations; they are adding to a fundamental change that helps the entire ecosystem. This holistic view of sustainability in product development strengthens its essential role in shaping the future of production.

Innovative Substances and Technologies

The combination of innovative resources is revolutionizing item design in automated factories, driving a more eco-friendly approach to production. Eco-friendly polymer materials and natural materials are increasing acceptance as substitutes to traditional substances, lowering environmental impact. These resources not only diminish dependence on fossil fuels but also provide unique properties that can enhance goods quality, such as flexibility and strength. This shift motivates manufacturers to rethink their logistics and explore local procurement strategies, resulting in diminished emissions linked with shipping.

Advancements in manufacturing technologies further promote sustainability objectives by improving efficiency and lessening waste. product design and manufacturing as incremental manufacturing, also known as additive fabrication, allow for accurate production, lowering surplus material usage. This technology enables the creation of detailed designs that were once unattainable, resulting in aerodynamic and practical products. Moreover, the capacity to manufacture on-demand mitigates the risk of overproduction, aligning with the concepts of a circular economy.

High-tech factories are also utilizing digital tools like the IoT and AI to improve resource use. These tools acquire instant data, enabling manufacturers to manage energy use and material usage throughout the production process. By analyzing this data, companies can introduce improvements that boost sustainability, such as adjusting processes to lessen energy consumption during peak times. Such advancements demonstrate how the combination of innovation and sustainability in product design is not just advantageous for the environment but can also drive operational excellence.

Incorporating Intelligent Production Processes

Combining smart manufacturing techniques into item development involves leveraging advanced tech to enhance sustainability. This means using information analytics, the IoT, and automated systems to increase power effectiveness and lessen disposal waste in manufacturing. By implementing these technologies, producers can observe results in real time, allowing them to align operations with green practices effectively. This adaptive approach allows forehand modifications that minimize environmental footprint throughout the production process.

Moreover, intelligent manufacturing enables the collaboration between design and manufacturing groups, streamlining operations while confirming that sustainability goals are achieved. With digital twins and simulation tools, designers can analyze the environmental consequences of their items early in the design phase. This advocates a more holistic approach to product development, where considerations for material procurement, power consumption, and recycling are included into the design process from the start.

Finally, the shift to advanced production methods links businesses with their distribution channels more efficiently. By encouraging openness and dialogue, manufacturers can make educated decisions that favor green practices among their partners. This networking enhances the ability to choose eco-friendly materials and optimize logistics, further contributing to the overall eco-friendliness ethos within goods design and manufacturing.